The first time does not join the gravitational waves, after the same time, the two beams of light return, and in the spectroscope to re-meet, resulting in interference. This time by adjusting the X, Y arm length, control the two beams are canceled, then the photodiode no optical signal. After the second test to join the gravitational wave, the gravitational waves from the direction perpendicular to the ceiling into the arms of the arm will be stretched, the other arm compression is short, so that the two light optical path difference has changed, the original coherent The conditions of destruction are destroyed, a certain amount of light will enter the detector, get the gravitational wave signal. The advantage of the most powerful laser interferometer for the resonant bar is obvious: First, the laser interferometer can detect a range of frequency of the gravitational wave signal is generally 20Hz-3000Hz; Second, the laser interferometer arm length can be done very long, such as ground gravity wave interference The arm length of the instrument is generally in the order of 1000 meters, far more than the length of the magnets of the magnets, so that the gravitational waves will be displayed through the photodetector.

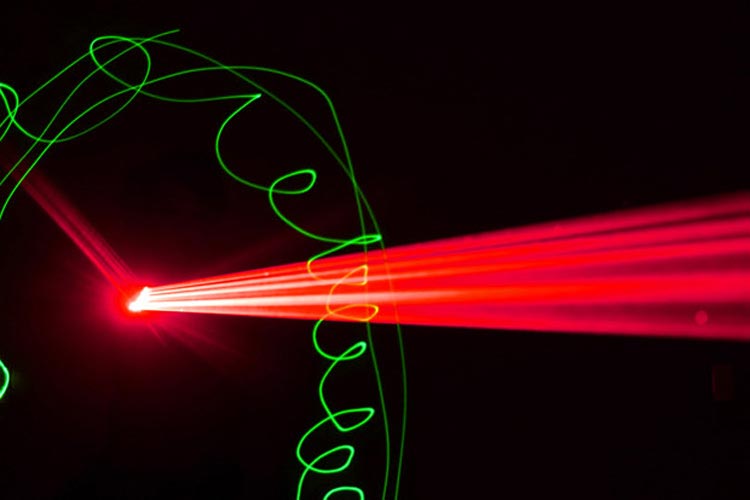

At the beginning of the production chain, aluminum or copper foil is first coated and compressed to produce an electrode foil. The anode needs to use copper, while the cathode uses aluminum as the carrier material. The foil is made through a coil and needs to be cut into flakes by a cutting or cutting process. The advanced technology currently used in the production process is mechanical cutting. However, the main drawback of mechanical cutting foils is that the cutting tool produces very high mechanical wear. Therefore, the tool must be replaced frequently, which will result in additional tool costs and fluctuations in the quality of the cutting. In the next step, the taps of the electrode foil need to be welded together. Today, the most advanced technology used in this process is green laser pointer welding or ultrasonic welding. The technical challenge in this production step is to weld thin foil with copper-copper, aluminum-aluminum or aluminum-copper and other materials. In addition, for high quality battery cells, the resistance value of the melting zone is required to be very low.

In recent years, further miniaturization and improved quality requirements for ultra-precision machining are growing. As a means of meeting this need, the use of short-pulse, short-wavelength laser processing methods has attracted attention. By using a picosecond pulsed laser, it is possible to achieve a cold ablation that does not produce a thermal effect, thereby obtaining a high-precision machining excellent in quality. In addition, the use of short wavelength lasers can make the laser beam spot diameter smaller, in order to achieve more fine micro-processing.

At present, common short pulse lasers for microfabrication are mainly green lasers (532nm), followed by ultraviolet lasers (355nm). On the other hand, a 266 nm deep ultraviolet burning laser has not been widely used due to its difficult handling.

Usually a small crack will cause the glass to break. Once the microcracks are formed in a part of the glass, it will spread to the edge of the glass, causing rupture. This fragile property of the glass makes it difficult to process. On the other hand, the evolving technology allows it to be made into smaller, and different shapes of glass for use in different areas. Traditional precision methods such as lithography and electron beam lithography to process glass, but these techniques are too expensive to operate, especially for large areas. Today, green astronomy laser technology provides the most accurate way to process glass. The most straightforward way is to use a single photon absorption in the wavelength range, the glass in the infrared or ultraviolet light will not be highly transparent.